We work to exceed Your expectations

The flapper valves are the most heavily stressed components in compressors for cooling systems. A long life durability of compressors is therefore linked to the fatigue resistance of the flapper valves themselves, and the use of hardened steels, specially developed for such heavy working conditions, may not be a sufficient measure. Accurate finishing treatments, which eliminate every possible microcracks sources, and the application of an external compressive stress (“residual stress”), are the key factors for fatigue resistance maximization.

While much work has been already done about special steels for flapper valves, the finishing treatments and the residual stress, which are the results of precise and standardized tumbling processes, still show promising room for improvement.

Vito Rimoldi has therefore started a project focused on the residual stress level achievable on flapper valves and on the optimization of the relevant production processes.

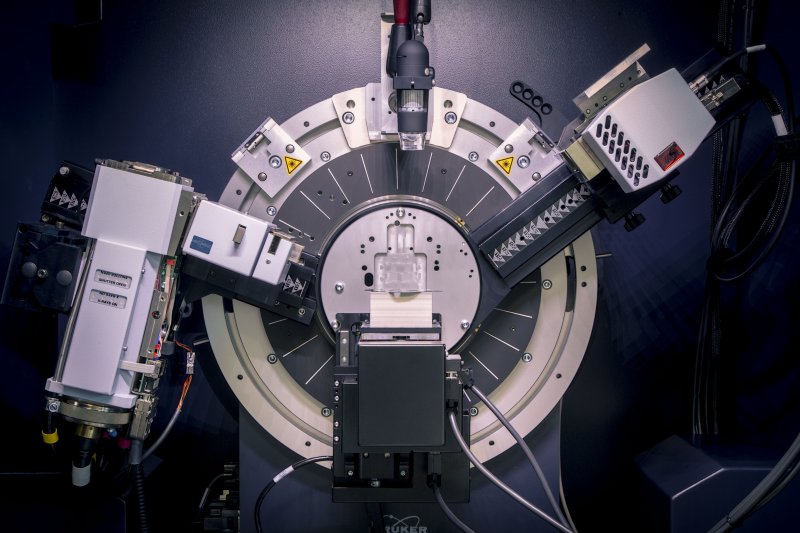

But since “if you cannot measure it, you cannot improve it” (Lord William T. Kelvin), our Company purchased a measuring instrument fit for that purpose: it is an X-rays diffractometer manufactured by the German Company Bruker. It is a highly valuable instrument, that enhances our laboratory and will enable us to increase our knowledge.

By means of this important investment, Vito Rimoldi confirms its commitment in continuously improving and innovating products and processes, in order to offer its Customers a support that consistently exceed their expectations.