These are metal-rubber gaskets that are blanked and deep-drawn using a sequential molding process. Metal gaskets are produced in large series to be used in industrial applications characterized by extreme mechanical and thermal conditions.

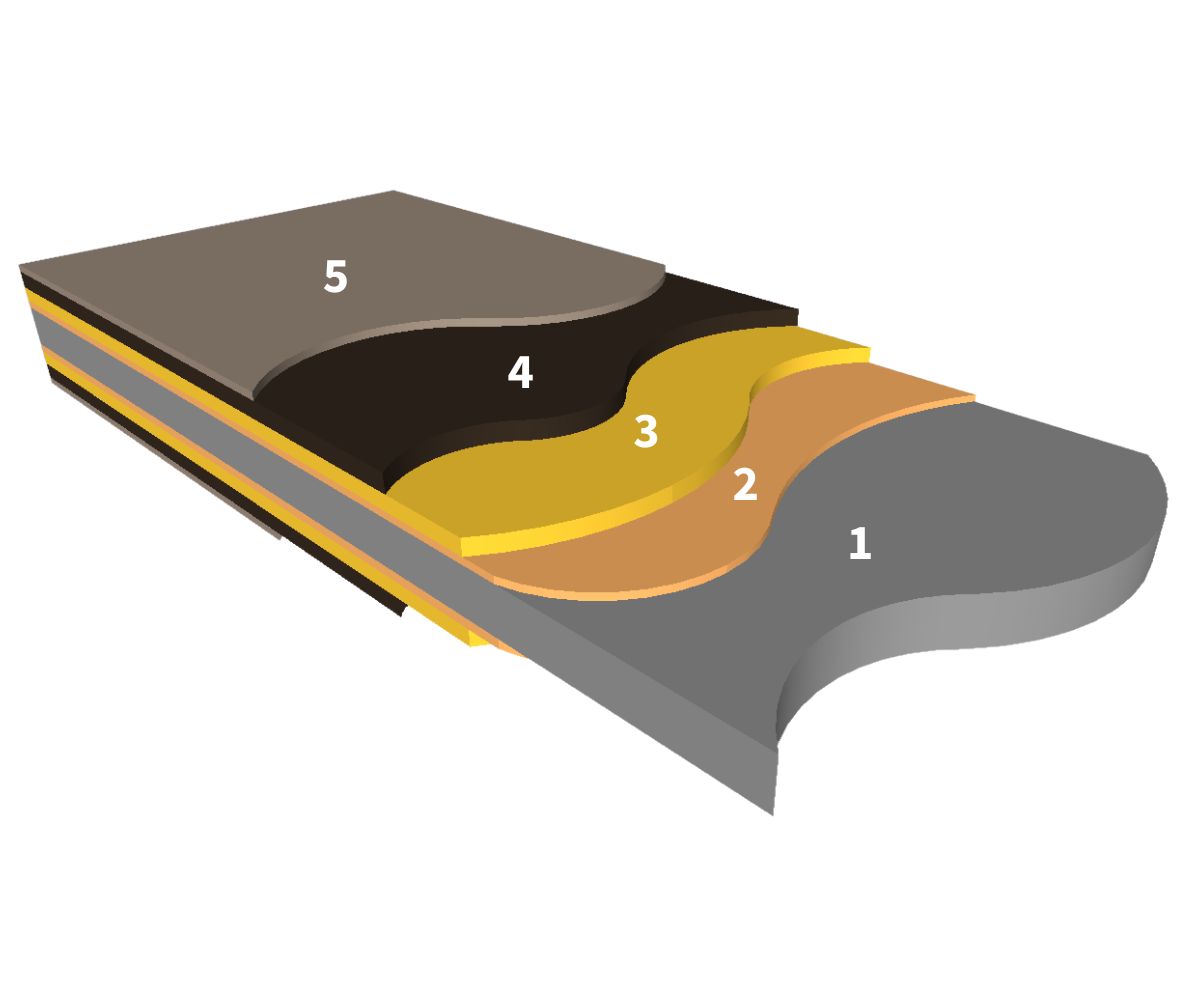

Material structure

The seals are made of a composite material consisting of a thin steel insert covered on both sides by an elastomeric coating.

1 - core made of carbon or stainless steel

2 - chroming to protect the metal

3 - primer to allow rubber gluing

4 - elastomer

5 - non-stick coating

Coinage design

A sequential molding process makes it possible to obtain simple or double coinages in the material.

These coinages allow the metal part of the gasket to deform during the crushing phase, adapting to the sealing surfaces. The special elastomeric coating also compensates for any microporosity of the flanges, ensuring the sealing of the contact areas.

Applications

Metal-rubber gaskets are used in applications with small contact surfaces, unfavorable geometries, low loads on the fastening screws, and in demanding conditions.

They are employed in the industrial field for compressors, gearboxes, pumps, and motors and in the automotive sector in car engines and in commercial vehicles, exhaust systems, water pumps, petrol pumps, and heat exchangers.

What sets us apart

- The elasticity of the metal combined with the elastomeric coating ensures sealing in applications characterized by extreme pressures.

- We can pack finished products using methods and quantities that are suitable for use with automatic assembly machines.

- We have very short prototyping and supply times for small pre-series.