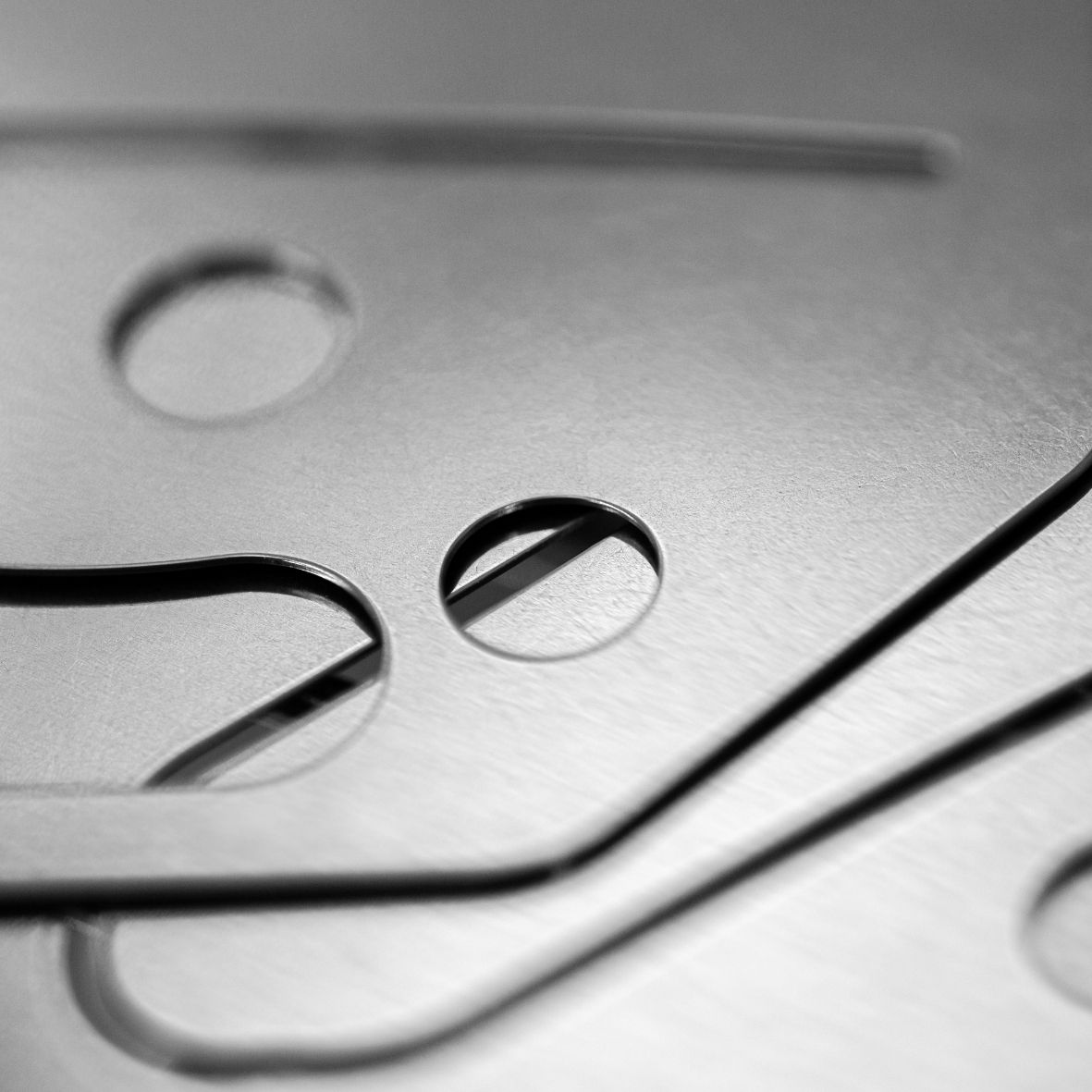

Reed valves, leaf valves, and valve retainers are mechanical components commonly used in refrigeration compressors in the civil, industrial, and automotive sectors for the regulation of the refrigerant gas flow during intake and unload.

The main characteristic of these valves is their capability to withstand the stress created by repeated bending without breaking.

Precision blanking

The quality of the blanking and of the finishing process determines the life expectancy of reed valves, which is typically several billions of cycles.

Punch pieces that respect the specific shape of the valves ensures correct assembly and coupling during operation. The absence of surface defects, such as scratches, roughness, and impurities, guarantees greater resistance to applied stress, temperature changes, bending, twisting, and impacts. Finally, precise blanking protects the valves from exposure to harsh chemicals and corrosion.

We are able to limit the width of the gaps between the moving and fixed parts of leaf valves to within a few tenths of a millimeter, thus helping increase the efficiency of compressors.

Tumbling and polishing

A “clean” blanking with little discontinuity, however, cannot wholly eliminate the risk of breakages—even if reduced to a minimum, the defects that can trigger them remain present.

For this reason, tumbling and polishing become necessary complementary processes. They consist of removing all of the imperfections that remain after cutting and increasing the residual stress on the components.

These processes require accurate evaluations to define parameters, such as the technology to be used to remove defects, abrasive materials, the protective agents that preserve the steel from exposure to chemicals and oxidation, the timing of the application of the finishing action, and the quantities of components to be treated.

The raw material

Reed and leaf valves are formed out of very thin ribbons of tempered steel, specifically developed for this application, and supplied only by a limited number of qualified manufacturers worldwide.

Our materials are certified by these manufacturers who attest, lot by lot, to their physical qualities and composition.

Carbon steels or stainless steels are used depending on customer requirements.

Our valves are manually packaged for each customer in antioxidant protective paper.

Carbon steels

ALLEIMA® 20C

VOESTALPINE UHB 20C

Stainless steels

ALLEIMA® 7C27Mo2

VOESTALPINE UHB SS716

Why choose us

- We use Bruderer blanking machines, which achieve the utmost in reliability and precision.

- We take care of the design and manufacture of molds, optimizing them for each application.

- We carry out studies and experiments to create finishing cycles that fully satisfy each customer's specifications.

- We conduct checks and measurements agreed by the customer, which allow supplies to qualify under a "free pass" regime (accompanying documentation included).