Tube forming machine for high pressure tubes

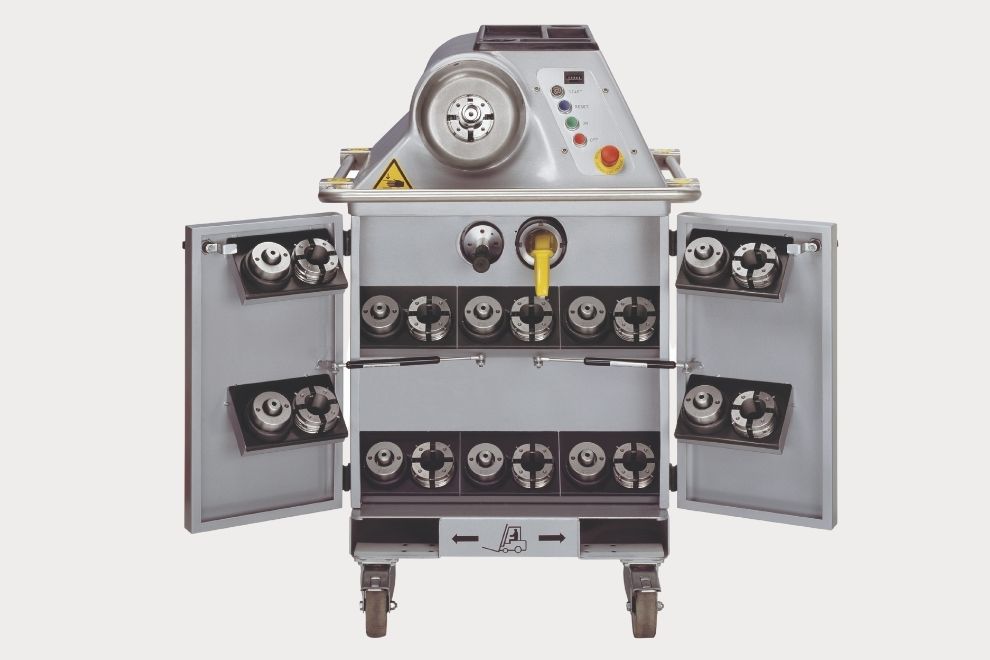

Vito Rimoldi's Fluid Connectors Division recently purchased Parker Hannifin's F3 WorkCenter. It represents not just a machine, but a complete tube forming workcenter, designed to cold-form high pressure tube for EO2-FORM connections.

For easy operation and high efficiency, the EO2-FORM process is completely automated.

During this process, the tube end is compressed in-between forming dies. This results in a special tube profile which matches the genuine EO-2 fitting components.

Our company bought a number of standard clamping dies that are suitable for all common hydraulic tube dimensions.

It is an attractive solution for its full interchangeability to the complete Ermeto Original product range according to DIN EN ISO 8434-1/ DIN 2353. The EO2- Form technology is not a new fitting system. It’s a product extension of the proven EO2-Plus System product range and of the EO-2 range which has existed since 1993. Exactly the same seal elements are used.

The high volume elastomeric seal “DOZ” assures a hermetically sealed tube joint. It is located in between the inner cone of the fitting body and the tube surface, thus blocking the only possible leak path. The sealing effect is pressure supported; even low-viscosity media such as water or gas are hermetically sealed. Moreover the elastomeric seal does not require any re-tightening even after years of operation under extreme working conditions.

The EO2-FORM machine can cold-form all common steel tubes used in hydraulic systems (also stainless steel and exotic materials such as CuNiFe).

A decisive advantage of the EO2-Form fitting system is related to safety: there is little danger of tube blow off if the fitting is not properly tightened. A loose joint shows excessive leakage before total failure.

With WorkCenter EO2-FORM-F3 Vito Rimoldi offers customers a reliable and cutting-edge technology. The machine can also be rent.